DM (Demineralized Water Treatment Plant)

Demineralization Water Treatment Plants (Dm)

All Natural Sources Of Water Contain Impurities As Well As Dissolved Gasses. The Amount Of These Impurities Depends On Type Of Water Source And Location.

Why It Is Necessary To Treat The Raw Water?

Raw Water Coming From Different Sources Contains Dissolved Salts And Un-dissolved Or Suspended Impurities. It Is Necessary To Remove Harmful Salts Dissolved Into The Water Before Feeding It To The Boiler.

Demineralization Process Involves Removal Of Minerals By Means Of Ion Exchange Resins. Demineralization Of Water Is Achieved By Passing Water Through Cation Resin Column And Then Though Anion Resin Column. Demineralized Water Also Known As Deionized Water, Water That Has Its Mineral Ions Removed. Mineral Ions Such As Cations Of Sodium, Calcium, Iron, Copper, Etc And Anions Such As Chloride, Sulphate, Nitrate, Etc Are Common Ions Present In Water.

Major Application.

Boiler Feed Water, Textiles, Pharmaceuticals, Chemicals, Breweries, Swimming Pools, Potable Water, Hospitals, Automobile, Battery, And Fertilizers.

The two most common types of Demineralizer

- Two-bed demineralizer.

- Mixed-bed demineralizer.

Two Bed Demineralizer.

Two bed demineralizer also called dual bed. Two bed demineralizer have the cation resin and in separate vessels. one containing a Cation-exchange resin in the hydrogen(H+) form and the other containing an anion resin in the hydroxyl (OH-) form. Anion resin must have the hardness removed from the influent water to prevent hardness fouling. The cation resin is regenerated with acid and the Anion resin is regenerated with sodium hydroxide.

To keep the water electrically balanced, for every monovalent Caution, e.g. Na+, one hydrogen ion is exchanged and for every divalent caution, e.g. Ca2+, or Mg2+, two hydrogen ions are exchanged. The same principle applies when considering anion exchange. The desalinized water then flows through the anion column. This time all the negatively changed ions are exchanged for hydroxide ions which then combine with the hydrogen ions to form water (H2O). Two Bed Demineralizers normally produce water quality in the range of 50,000 ohms up to 200,000 ohms resistivity, which is between 8.5 and 2.0 ppm TDS as CaCO3. Automatic mixed deionizers utilize the same resins but mix the two resins for use. This produces a significantly higher purity than two column design, up to 18 megohm

Mixed Bed DM Plants.

Mixed bed DM plants is a single vessel unit, which combines cation and anion exchanger in a single column. When it comes to require high-purity demineralized water, mixed bed demineralizer is considered more efficient in many ways. It is used as poishing unit to purify water to higher levels, which is treated through two bed demineralizer or reverse osmosis unit at earlier stage.

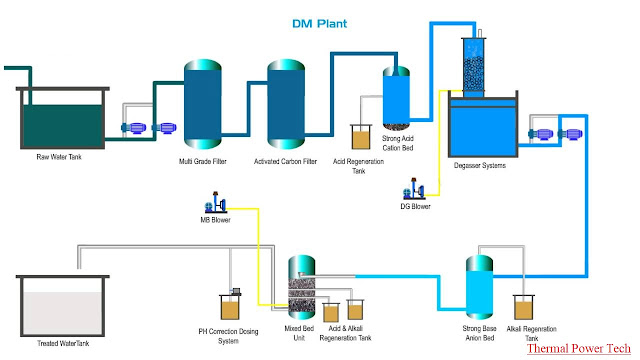

Water demineralization system consists of various combinations such as:

[(MGF) – ACF – (SAC)] or (DMF) – (DG) – (WBA) – SBA – (MB)

- MGF : Multi Grade Filter

- ACF : Active Carbon Filter

- SAC : Strong Acid Cation

- DMF : Dual Media Fliter

- DG : Degasser

- WBA : Weak Base Anion

- SBA : Strong Base Anion

- MB: Mix Bed

MGF : Multi grade filter

Used to remove the escaped flocks from clarifier

ACF: Active Carbon filter

It’s used to remove the excess content and coloring matter to avoid resign damage. It’s also work as a filter.

SAC : Strong Acid Cation

It’s used to remove all the positive radical of dissolved salts present in the raw water.

DG: Degasser

The function of degasser tower is to remove carbonate ions by forming carbon-di-oxide. In degasser tower stream of water is poured from top and air is blown from bottom to top. In the pressure of air the carbonic acid (H2CO3) present in the water dissociates into H2O and CO2. H2CO3= H2O + CO2

This CO2 is free to mix with air.

Benefits of using degasser are:

- It removes the carbonic acid and other gases mixed with water by simple physical method and thereby reduce the chances of corrosion.

- It saves the resins which are very costly chemicals and thereby improves the economy of boiler feed water treatment process.

The H2CO3 free water is now collected in degasser sump and then pumped to anion exchange resin inlet.

WBA: Week Base Anion

It’s remove face mineral acid in the water.

SBA: Strong base Anion

It’s remove residual carbonic acid and silica from the water.

DM Plants Regeneration.

Depending upon frequency of use and DM water output, resin become exhausted and does not capable to deionize in other words, there power of removing ionic materials reduces and active ion concentration reaches a low level. The process of restoring their power or enhancing active ion conecentration level is called regeneration. In this process exhausted cation and anion ions are recharged with hydrogen (H) hydroxyl (OH) ions.

Demineralization plant employs a chemical method to separate out the dissolved salt in raw water. But reverse osmosis plant employs a simple physical method to separate the dissolved salts. Before feeding the raw water to these plants sand filtration is done by different filters. Along with these plants there are two deaerators, which remove dissolved oxygen in the feed water, as traces of oxygen may react with boiler tubes and thereby corrode those.